Your Strategic Partner for

Unlocking China's Sourcing Potential

How to prevent delays from China suppliers?

In China’s manufacturing industry, many things can not be said in common sense.

If you have ever purchased from China, you will find that most of the suppliers can not deliver on the promised delivery time. And they’re gonna tell you a whole bunch of reasons. For example, equipment is broken, there are not enough workers, or did not anticipate the difficulty of production and so on.

We are far away from home and may not be able to tell the truth of what the supplier has said. Then what we should do is to avoid the occurrence of delay in delivery?

How does the factory schedule orders?

Pay high attention to strong buyers

In production, Chinese factories often encounter situations where each salesman says his order is urgent. Why is that? This is very understandable. If your order is not in a hurry, the workshop will arrange your order to be produced behind other orders, and other salesmen will put your order in front of your order when they receive a new order.

Therefore, many companies will take such a method for order scheduling. The order amount of all customers in the past year, the order quantity of customers and the average customer unit price of each specification and variety in each order were extracted, and the customers were divided into three categories: A, B and C. According to the customer classification, the salesman will mark the classification on the order.

In the same case, the factory will give priority to the orders of Class A customers, and the orders of Class C customers will be placed last. Of course, if you are a potential new customer, the factory will also evaluate you and decide whether to prioritize your order.

So the smart thing to do is to let the supplier see you as a potential customer. You can tell the vendor your marketing plan, tell the customer your next order quantity and so on to win the customer’s attention.

Sort out product categories

This is also one of the most common methods of scheduling in factories.

According to the material, process and cost, make A model to classify the current company’s various specifications and varieties, which are also divided into A, B and C.

In the production process, the factory will put the products of the same technology and the same material together to achieve the scale effect, save the processing time difference and improve the working efficiency of the workers.

With the classification, the production planner no longer needs to schedule production according to experience, but according to classification, according to the production schedule.

So when your order is small, the factory is likely to combine your order with other orders to cover costs. There is nothing wrong with this in itself, but if there are no other orders of the same product at the time of your order, the supplier will put your order aside and arrange production together when there is another order of the same product.

Combine customer and product

By combining customer classification with product classification, suppliers can clearly see the status of each order.

According to this classification, the supplier will make the production operation plan for the current quarter.

In this way, on the one hand, it is conducive to the communication between sales and customers, and in the case of insufficient production capacity, important orders from important customers can be guaranteed.

On the other hand, it is also conducive to the production organization, the same process and the same material products combined production, improve productivity efficiency, save costs.

Roll up the plan

The factory will have some emergency orders every day. After sorting orders, the factory will determine which are really urgent and which do not need to be arranged in advance.

The plan is rolling, that is, every day the schedule is actually 80% of the production capacity, and in this 80%, maybe 20% of the orders can be postponed. In this way, the truly urgent orders that day are guaranteed to be completed. That is to use the 20% of capacity that is not arranged to complete the urgent order of the day. Of course, when the urgent order volume of the day exceeds 20%, there are two considerations: one is to arrange overtime, and the other is to put off the other 20% of orders that are not important.

In this way, the plan is rolled, on the one hand, to ensure the priority of orders, on the other hand, the production site will not be easily disrupted.

These are some of the most common methods of scheduling in Chinese factories.

Why do China suppliers always delay delivery?

Every buyer will encounter the problem of delayed delivery in their work. From the beginning of the order to the end of the delivery, it seems a very simple task, but the supplier can never complete the delivery on time. Although deduction of payment can be a punishment, it does nothing to make up for the shipment.

Before we start, let’s analyze how the product is produced. We all know that each product needs dozens or even hundreds of parts. Some of these hundreds of parts are produced by the factory, and some need to be purchased from other places. From raw material preparation, proofing, quotation, evaluation of the factory, and samples confirmation, order production, this whole process takes a lot of time.

Analyzing from the time point, delayed delivery is understandable. But from the standpoint of the company, it is not allowed. What should the purchaser do at this time?

In many cases, the reasons for delayed delivery of orders are as follows?

1. In terms of production status: the production capacity is fully loaded and orders cannot be placed into production. For example, when raw materials are not in place in time, suppliers often forget to estimate the condition of raw materials when they respond to the buyers about the deliveries. Most suppliers only estimate the daily production capacity of the machines and equipment. When there is a shortage of raw materials or incoming materials, they can only do nothing. So when discussing the delivery date, it is best to ask the raw material supply status, such as the origin, market, quality, and delivery date.

2. In terms of production technology: because the number of orders is too small, the supplier combines several orders to produce.

In this process, many salespersons will give you various promises in order to win your order, and perfuse the problems that occurred during the production process. When the order is officially produced, it is found that the materials are of special specifications and the molds have special specifications. Many problems in production were not encountered or foreseen in proofing.

Or the secondary processing or surface treatment of the product is not sound in the supply chain, causing the problem to be unable to be resolved and affecting the delivery date. Therefore, when discussing the delivery date with the supplier, pay attention to the supplier’s attitude towards the problem in production. It is best to tell the supplier of the problems encountered before and pay attention to handling during the production process. For those suppliers who pat their chests to ensure that there will be no problems, be especially careful.

3. In terms of production management: production technology cannot keep up with the needs. The defective rate and heavy work rate in the manufacturing process are too high. The production plan is inappropriate. The internal shipment inspection failed.

This is mainly reflected in the condition of the equipment. Although some factories are fully equipped, the equipment utilization rate is not high, and maintenance is often performed. The production is already full and there is no redundant machinery to produce.

Many salespersons will say that I will arrange to insert your orders\ into production. This is just a means for salespersons to stabilize customers. When he says these things to you, he also says the same to other customers.

The production schedule of a factory is jointly completed by many departments. The salesperson will hand it over to the production management department after receiving the order. The production schedule set by the production management department cannot be changed at will. The buyer should accept this point, pay attention to the supplier’s production schedule, machine capacity, equipment maintenance and maintenance status when evaluating the factory before placing an order.

4. Personnel management: Although many machines have replaced labor, manpower shortage is still an inevitable problem. The salary of factory employees, the turnover rate of employees, the quality of employees, etc. all affect the normal production of the factory and thus affect the normal delivery. Of course there are other factors, such as production resources, lack of materials, social facilities (water, electricity), etc.

Of course, we do not rule out poor schedule management, failure to implement the quality control system, wrong estimation of delivery time, wrong shipping documents, wrong quotation, lack of responsibility of suppliers, etc.

Of course, sometimes the buyer is also responsible for the supplier’s delay in delivery. Please recall:

- Have you clarified all your requirements for the product?

- Does your supplier agree to the delivery date you requested?

- Have you provided the design draft to the supplier in time?

- Do you always confirm samples from suppliers in time?

- Have you changed the product design after placing an order?

If not, great. If so, you should first improve your own work process, and then check whether the supplier has delayed delivery behavior.

Solutions for delayed delivery

Delayed delivery will certainly bring some losses to buyers, such as reduced customer satisfaction, resulting in additional logistics costs, customer loss, missed sales season and so on. In short, it will cause a lot of negative impacts on the buyer’s business.

Then when the late delivery is about to happen or has already happened, what should the buyer do to reduce their losses and protect their interests?

1. Shipment in batches. Shipment by installment, also known as shipment by installment, is the shipment of goods under a contract in several phases or several times. In international trade, where the quantity is large, or limited by the source of goods, transportation conditions, market sales or capital conditions, it is necessary to ship or arrive in installments in installments, the installment shipment clause shall be stipulated in the sales contract. In order not to make customers out of stock and affect sales, the method of shipment in batches can be considered. Buyers can require suppliers to arrange shipments of completed products within the delivery period. If the delay is caused by the supplier’s error, the supplier can be required to pay for the additional freight incurred by partial shipments.

2. Optimize the logistics plan to make up for the loss of time in the production process.

Suppliers are required to change their transportation methods and use faster transportation methods. For example, sea transportation is changed to air transportation, and air transportation is changed to express. Although the transportation time is greatly shortened, the cost is also much higher. Therefore, this method is more suitable for orders with fewer products. For large orders, this method is usually not used as a last resort.

3. Use the remaining available time to urgently raise production capacity. This mainly depends on whether the supplier can do it. If the supplier can increase production capacity by working overtime and recruiting temporary workers to ensure timely delivery, that would be best. But also pay attention to the problem of suppliers lowering quality standards in order to catch up.

4. Get in touch with the top of the supplier. In many cases, salespersons are the ones who contact customers, and their rights are limited. They can’t interfere with the factory’s arrangements, and the factory will not listen to salespersons. The best way at this time is to get in touch with the supplier’s boss. The bosses of Chinese suppliers have unlimited rights. As long as the boss promises, it can be done.

5. According to the contract, notify the supplier to cancel the purchase contract. And require suppliers to compensate for economic losses in accordance with the contract, and at the same time choose a new supplier or find a spare supplier to purchase.

7 tips to avoid delivery delays

The delivery delay is a big problem. The supplier always causes the delivery delay for various reasons. In the end, the customer has no choice but to be angry and forced to accept. You can’t fly to China for an order to find a supplier trouble! So the question arises, how to avoid delivery delays?

1. Summarize the factory’s production habits and determine the normal delivery period. If the relationship with the factory is good, you can give the factory some suggestions for improving management. It is better to find the cause than to find the reason.

2. Choosing a supplier is very important. Don’t look for large, domineering factories, but find a medium or small scale (with support value), good quality, and high degree of cooperation.

Let the factory give the start date of order production, daily routine output, and estimated end date. If the factory regards you as its main customer, you can even ask them to make a production schedule and update it for you every few days, so that you can have a clearer grasp of the production situation.

3. Suppliers who often delay delivery will indirectly affect your costs and profits. Therefore, it is recommended to evaluate suppliers regularly.

4. Frequently communicate with suppliers to understand their recent orders and production status. When the factory is in difficulty, such as placing an order to the factory during the off-season, it may help the factory tide over the difficulties and even save the factory’s life. In this way, the factory will do its best to help you during peak seasons. On the contrary, the factory arranges your order to the end when it is busy.

5. Don’t completely trust the factory, sometimes the factory will be pressured to tell you that the goods are finished. You should ask the factory to take a few photos to show that they finished the production. Even hire a Chinese sourcing service company to help you go to the factory to check the real production situation and progress of the factory at any time.

6. For some orders with relatively high delivery time requirements, tell the factory that the delivery delay cannot exceed * days, otherwise the shipping schedule will be delayed. The consequences are borne by the factory.

7. Large orders need to be notified to the factory in advance to avoid the situation where the factory is busy and other customers have already promised delivery. Try to let the factory know your order cycle so that the factory can consider you in the production plan.

How to monitor the production progress?

Strictly evaluating the supplier is the most important thing before placing an order, and the most important thing after placing an order is to follow up the production progress of the factory and monitor the progress of the intermediate process.

This article will introduce some nodes that you need to monitor after placing an order. Allows you to discover abnormal factors that affect efficiency through production progress monitoring to ensure that products are shipped in quality and quantity on schedule.

Although various production industries have different strategies when monitoring production schedules, the key points are always the same! For production progress monitoring, we usually do: monitoring before production and monitoring during production.

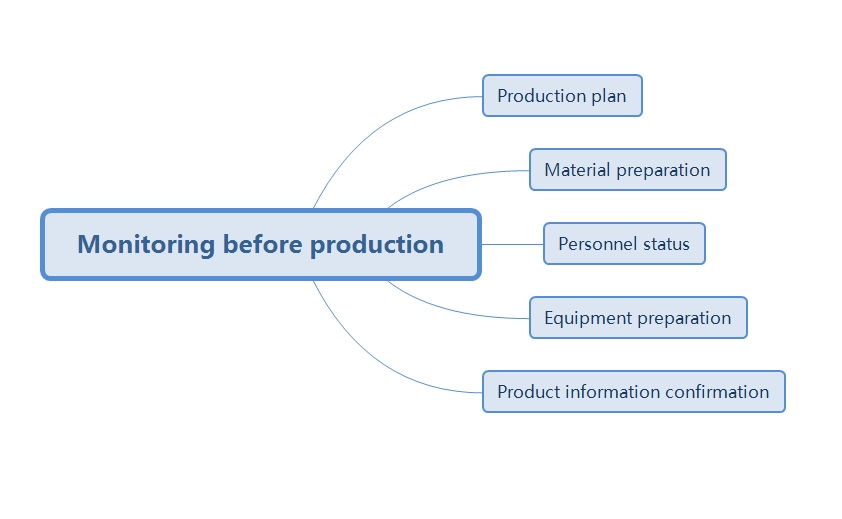

Pre-production monitoring, that is, the production plan, material preparation status, personnel status, equipment preparation status, product information status confirmation. We should keep close contact with the supplier, ask for the progress of the supplier at these times, and let the supplier take photos to prove the authenticity.

If you ask the factory how about the material preparation, if the factory did not give you an accurate answer which day the material will be in storage, then you should focus on following up this work. Ask the supplier about the material readiness every few days and put pressure on the supplier to take this issue seriously.

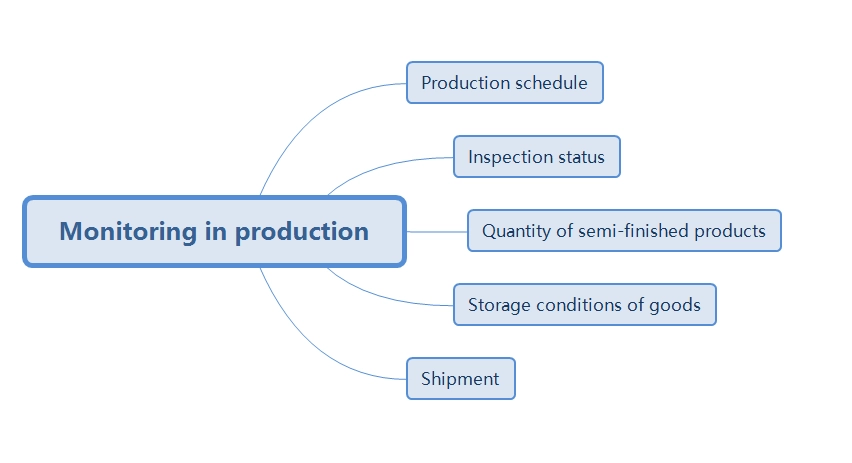

Monitoring in production. Pay attention to the frequency and tools of progress monitoring, verification of inspection status, verification of semi-finished products, verification of storage status. You can ask for the quantity of semi-finished or finished products 10 days after the supplier tells you the order is in production to estimate the daily capacity of the plant and approximate delivery time. For very large orders, you can even ask the supplier to update the order production schedule to you periodically.

The most terrible thing is not the delay, but the supplier will not take the initiative to tell you that there is a problem with the order. They always tell you that they have to delay the delivery when the delivery date is about to come, so you are caught off guard. Therefore, it is very important to monitor the progress of the order, so that we can know the real situation of the order, know and discuss the solution with the supplier as soon as there is a problem.

Conclusion

In practice, the situation may be more difficult for purchasers, but there are always more solutions than difficulties. Master the two core skills – evaluating suppliers and following orders – and there will be no more late deliveries.