Your Strategic Partner for

Unlocking China's Sourcing Potential

The Ultimate Guide to Sourcing PCB Components

PCB isn’t an ordinary business. With 76 billion USD in the pocket, it is ringing the nerves of top business companies. Whether you are an individual seller or an established brand, it can be a one-in-a-million opportunity.

Won’t you take it?

But before you purchase an electronic component, there are several quality factors to know about. You must know your suppliers, types, benefits, and tips. We have added A to Z details on electronic component sourcing.

1. PCB Basic Idea

1) What is PCB?

PCB, or printed circuit board, is the basic unit of all the electronic devices you find today. From simple machines to futuristic devices, all have PCBs in their constructions.

It comprises several components such as conductors, inductors, capacitors, etc. All serve to provide excellent support to the devices.

2) Where do you use it?

PCBs are very popular in various applications. Here is a quick list of applications where you can find PCB uses.

- Medical Devices. All CAT scanners, infusion pumps, and medical devices use the PCB circuits.

- Industrial equipment. Many industrial machines and control systems deploy the PCB.

- Consumer Electronics. Computers and smartphones are the most prominent examples where PCB served as a building block.

- Lights having the LEDs as a central component have the PCBs.

- Automotive industry. Nowadays, car navigation systems deploy the PCB circuits to get the expected results.

3) Is it a profitable business to start?

Yes. You can save higher margins by starting the PCB business. Up to 50% margin is not a minor deal. To raise your margins, grab the quality from suppliers and sell it to the consumers. That is when you’ll turn up your sales levels.

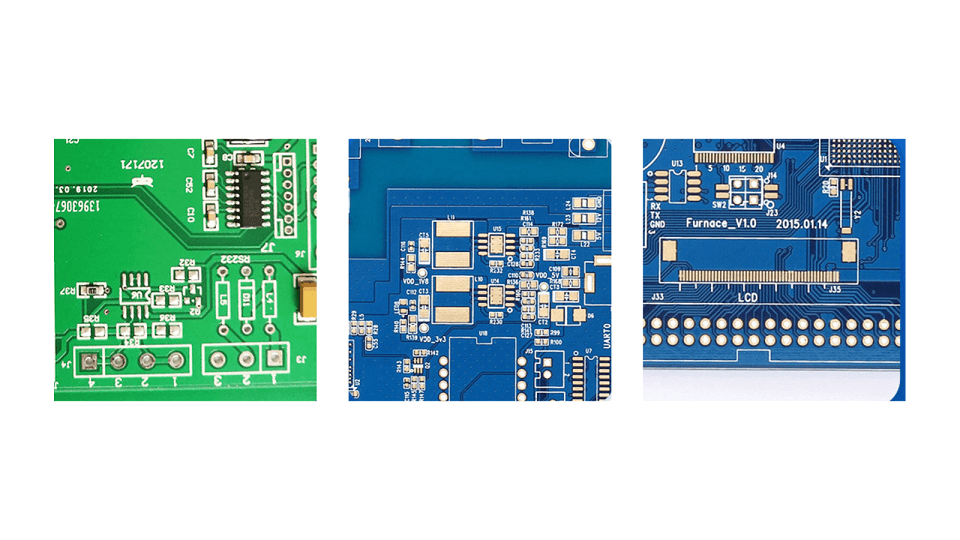

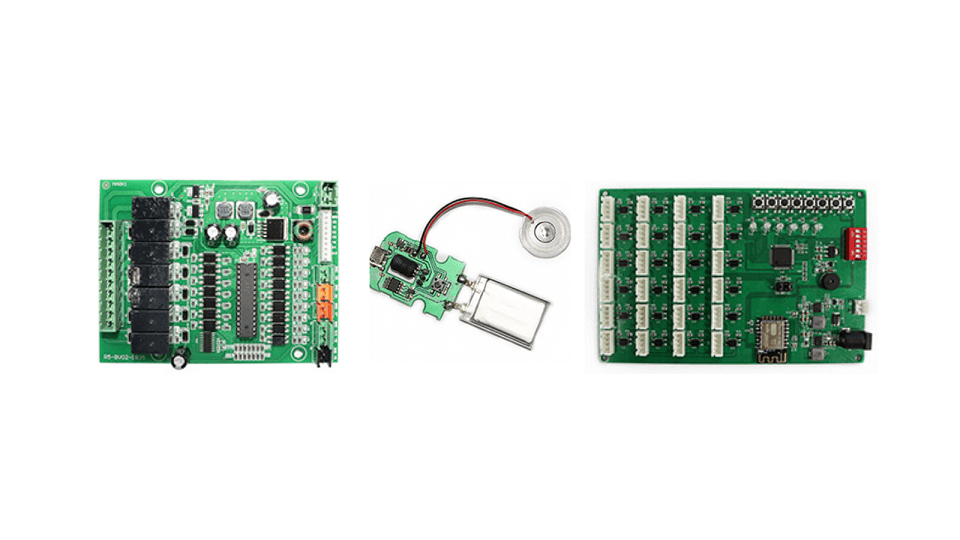

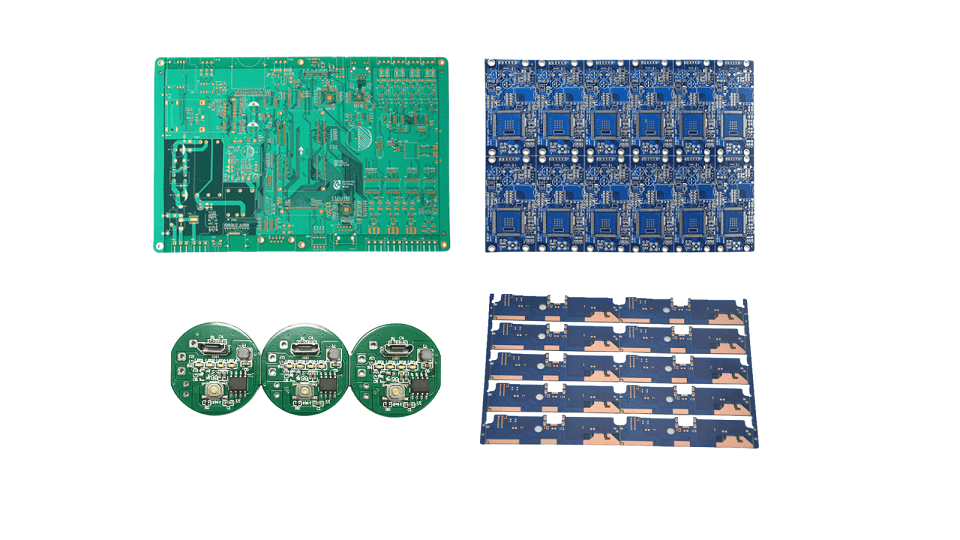

2. Types of PCB Circuit

Almost all types of PCB circuits serve one single purpose as the building blocks. But their composition can be different, leading to other costs. Here are three critical types of PCB circuits.

● Rigid

A rigid PCB circuit is often cheaper and comprises the rigid substrate fiberglass. They have less versatility but better affordability thanks to more accessible and more affordable production processes.

● Flexible

Flexible circuits retain their significance due to bending and angled foldings. Their ultimate flexibility puts them in use in different applications and allows for better uses. Their construction is expensive compared to the rigid PCB structures.

● Hybrid

Hybrid PCB boards are the revolution in the industry. Their flexible and rigid properties make them lightweight and suitable for almost all types of devices. They can be expensive compared to the above types.

3. Factors To Consider When the PCB Components

In electronic components purchasing, you can’t disregard the proper steps to take. It can lead to increased errors and quality scams. Before you even do electronic component sourcing, look for the following things.

● Determine your business needs.

Suppose you want to sell your PCB circuits domestically in a brick-and-mortar store or Internationally on online platforms. Spend some time thinking about your business and know your demands.

How many PCB circuits do you need? Do you have a budget for the products? Do you have a shipping facility? How big is your business?

Answering all these questions will put you ahead of others for the proper purchase of electronic components.

● Prepare a PCB design.

Working on a PCB circuit saves your hassles. You might understand whether the prototype will work out or not.

Once you have determined the electronic circuit and its mechanism, inform the suppliers.

● Use dimensions of standard-size boards.

Gather information about the standard-sized boards. Whenever you are preparing your prototype, ensure it matches the PCB boards. If you have a custom supplier, use their resources to prepare the standard boards.

● Use multiple tools to design it.

Since you need to provide the design in a downloadable format, use different tools. Usually, a Gerber format is the final output. The software can help you make this format design and provide it to your PCB manufacturers.

● Check for defects.

Before you go for the production, invest time. Double-check your PCB design and make sure it works out. Otherwise, the production will result in incompatible PCB boards. The result will be a monetary failure.

You can check for defects once your production has been done. The supplier offers you the product. Hire a top inspection company and evaluate all the defects. These will require replacements on time.

● Futuristic Use

Don’t you think a PCB board is your future? Let’s make it different and unique. Think about the future designs of the PCB and start designing your first samples.

Once you’ve completed it, check whether it works for the 2030s or future designs.

● Budget

A successful business owner keeps an eye on both the pricing and budget. Plus, you can take a pledge to raise your profit margins. Confirm the costs of PCB circuits from your suppliers. Mention you want bulk production in the electronic components sourcing.

They might give you some discounts on electronic parts sourcing.

● Longevity

Who wants to buy a crap? Don’t fall for low-quality electronic components procurement. Confirm the durability of all the elements. Moreover, ask the supplier about the warranties.

That is how you land the electronic components sourcing.

4. Buying Process

Electronic component sourcing is child’s play. You must know the following steps to land your first electronic components procurement.

● Find a supplier

First of all, find a supplier with whom you’ll work. If you already have it, that’s great. Otherwise, you can try online platforms such as Alibaba, Dhgate, or Made-in-China.

Moreover, trade shows or Google are also excellent choices. Conversate with your supplier and know about the company info before you land the purchase.

● Look for the best quality PCB components.

Customers only love to buy quality PCB boards. That means you can rely only on the quality components.

For this part, you should talk to the supplier. Ask for their offerings and quality control systems. Also, get real-time factory images to understand how the supplier processes the best quality.

● Confirm the quote.

Are you sure the supplier is 100% trusted and reliable? Go an extra mile to get the quote. If you are going for bulk production, tell the manufacturer and grab a suitable quote. Some suppliers offer lower prices if you order them in bulk inventory. Therefore, you should negotiate the prices.

● Compare the prices.

Don’t rely on one supplier only. Instead, list 5-10 top manufacturers. Talk to all of them. Know their quality. Obtain the quote for your business. Let’s see who offers the best quality at the lower costs.

Have you got all the quotes? Now, compare all of them. Categorize the prices, quality, and shipping systems. Filter out the best supplier based on your comparison.

● Ask about relevant certifications.

Certificates are documents that exhibit all the safety details about the products. For example, your PCB circuits don’t get extreme heat. Many international companies, such as ISO, UL, FCC, and many others, offer circuit testing and relevant certificates.

Certificates are necessary for selling products. Not just certificates from ordinary labs but also UL-verified labs. Therefore, ask what types of certificates they offer.

● Hire inspectors to test the quality.

Do Quality testing in three different phases.

- Get a sample. Test it in the lab.

- Go for the pre-production analysis of the factory area.

- During production, you can test the manufacturing process and product quality.

- Before shipping, you can again check the quality.

Work with the experts for the testing process to attain flawless quality levels.

● Work with sourcing agents to streamline the buying process.

Sourcing agents must be your long-term partners to increase work efficiency and reduce work burden. They know the local suppliers. Understand the market conditions. The chances of errors or scams are almost none. Moreover, they get you quality products with their inspection services.

Therefore, streamline your component procurement process with the sourcing agents.

5. PCB Testing and Quality Control

PCB testing and quality control are crucial in electronic components procurement. Look for the following types of testing and inspection in the electronic components sourcing.

● Pre-production analysis

Pre-production inspection is in the best interest of the consumers. It ensures your prototype works 100% perfectly. There are no errors that could decrease the customer hassles.

There are various types of analysis in this process.

● Electrical Testing

Electronic equipment uses connections and systems to perform. In the electrical connectivity, we have to check whether PCB circuits have perfect connections. Moreover, we test its short, open, and impedance values. There are two types of electrical testing. These include:

● In-circuit test

To conduct an in-circuit test, you need to have the custom fixtures and test programs. That is why it can be expensive, but results are accurate and effective for your business.

The test fixture makes contact with the board and checks its working systems.

● Flying probe test

A flying probe comes in contact with the testing points of a PCB circuit. Compared to the in-circuit testing process, it is super affordable. You don’t have to deploy the custom fixture. The drawback is the slow speed if you want bulk inspection.

● Visual Inspection

Experts need to handle it. They must know about every single part of the PCB. So, it involves checking the circuit’s defects, joints, and soldering. There are two methods to do it.

● Manual

In the manual method, experts have to be in person. Get a magnification glass. Notice if there is any defect. Check the defect. It is a better and more effective option. Do you know why? Because experts know how to find suitable holes in the system compared to automated systems.

● Automated optical inspection

Manual methods have risks of human error. How do we reduce it, then?

Automated methods are still there to help you. In this method, high-quality cameras and automatic machines detect the defects. The benefit is quicker results. You get accuracy. There are minimal chances of errors in this process.

● Functional Testing

One of the most crucial steps is functional testing. It involves the application of power to test all the components. If any element is not working, you can find it on time. It tells functional defects, unlike upper methods that detect functional defects.

During production inspection

Are products being manufactured? Takes some time. Go for the structural inspection. Perform it with automated tools to minimize errors. Later, try out the functional inspection.

Once you are sure of the best results, it is a green signal. Go ahead!

Pre-Shipment inspection

Before you load the products, let’s take the final test. You can apply all the above inspection methods and know any defects. Correct them by requesting the manufacturer. If there are no defects, you are good to go for shipping.

6. Importing PCB components

Have you ever imported products from one country to another? It can be a bunch of complex documents. Plus, you need to know Chinese government rules. Importing from China usually relies on suppliers. But you still have to take care of customs sometimes.

Howеvеr, here are some critical steps to understand it.

1) Confirm whether suppliers ship or not.

Before you finalize the deal, ask about the shipping. Keep some questions in front.

- Does the supplier ship?

- If a supplier ships, how does it work?

- If the supplier does not, can they arrange the shipping?

- Who will handle the customs?

- Do you need to pay customs duties, or will the supplier?

All these questions iron out the weeds of your business. You can better understand whether you need to arrange shipping or not. Moreover, it helps with customs processes as well.

2) Hire a shipping provider.

Suppose your supplier does not ship. What will you do? It is simple— hire a shipping service. You can visit Alibaba. Check out the variety of companies.

Here are some tips for smooth shipping.

- Sift through 5-10 shipping companies.

- Ensure they have enough transaction history.

- Check their company status.

- Talk to their team regarding the shipping process.

- Know about their charges.

- Compare costs.

Once you get prices for each shipping option, the cost becomes transparent. You can compare the costs of different suppliers. Determine who offers the best shipping but at lower charges.

That shipper is the one you should consider.

3) Choose shipping options based on your orders.

Standard shipping options include:

- Express shipping. It is a suitable method only if you weigh 30-35 kilograms. Express shipping is the most expensive option.

- Air shipping. If you weigh 100kg, air shipping is a good match. But choose it when you want fast shipping services.

- Sea shipping. Sea cargos are the cheapest options. You don’t have to pay very much. An FCL gets relatively faster shipping than an LCL.

Consider all the factors:

- Shipping speed.

- Dimensions of your products.

- How fast do you need it?

If you’ve decided, it can be the right time to talk to the shipping service.

4) Handle customs.

In local shipping services, there is no customs inspection. If you are shipping globally, customs interfere. Get your waybills, product costs, HS codes, and all required data ready.

You have to submit the customs fees, import duties, and inspection charges. Double-check whether you are shipping allowed products with relevant certificates. Any discrepancy in the documents leads to a halt in shipping. It is a problem!

5) Receive products.

After customs clearance, you can receive products at your doorstep. Ask the shipping service about whether they will ship to your doorstep.

If they do, get your products on time. You can also track your orders as some companies offer this facility.

7. Top 11 PCB Component Manufacturers in China

In electronic components purchasing, a reliable supplier is necessary. Without proper supply chain procurement, your online business can’t flourish.

Here are the top 11 suppliers for PCB sourcing.

1) Founder PCB

Founder PCB has led the PCB component sourcing for years. It has been working since 1986 and has produced a variety of electronic components. You can get rigid to flexible electronic components for your business quite quickly.

- Four factories. If you want the bulk production, four factories are there. Founder PCB meets your demands efficiently.

- Independent R&D institute. No more worries about the innovative designs. The research team is ready to dress up your dream designs.

2) SUNTAK

If you want a supplier from Shenzhen, Suntak is the right choice. Founded in 1995, it has established its image as a top-tech manufacturer of PCB circuits.

SUNTAK products have a variety of applications, such as cellphones, computers, and the automotive industry.

The benefits are:

- Quality PCB circuits. SUNTAK focuses on quality production. Therefore, you can find quality control in their production and grab different certificates.

- Nine factories. Do you want to produce 100s of PCB boards? Nine factories accommodate it.

3) Aoshikang

If you want a PCB supplier with excellent quality, don’t forget it. Since 2008, this supplier has provided consumers with all the solutions. From flexible PCB to rigid, get all types of solutions. Plus, their shipping is impressive, fulfilling all your dreams for doorstep delivery.

Here are some of the benefits of working with this supplier.

- Variety of products. No matter what type of circuit you need, believe in Aoshikang. They get you quite quickly. Plus, their boards are used in various tools because of their quality.

- Complete shipping. You don’t have to find any shipping provider when working with Aoshikang. It has a well-established supply chain mechanism. Let them know the address, and you get the products.

4) Shengyi electronics

Have you ever been to Guangdong? Find out the Shengyi electronics out there. It has been working in this industry for more than three decades. Founded in 1986, Shengyi Electronics provides consumers with PCB boards for different applications.

The benefits of working with this supplier include:

- Best quality. Quality is unquestionable. You get all the products passed from an excellent quality system.

- Reasonable prices. Costs are not as high as those of many other suppliers. So, you save more and make more. Don’t you want that?

5) Baoding Technology

Baoding technology is leading the industry with its innovative solutions. Copper-focused PCBs are just marvelous. It has been working since 1989 and has provided consumers with various PCB options.

The main features are:

- Latest technology. Baoding deploys the advanced equipment to manufacture. Therefore, PCB component procurement is in your best interests.

- Quality boards.

6) ELLINGTON

Are you looking forward to high-precision boards? Ellington is there to supply products. From double-layer to multi-layer PCBs, you get all from this supplier. The quality is next-level.

The main benefits are:

- Quality PCB. Only quality electronic components are the motto of this supplier. You won’t miss integral PCB circuits.

- Competitive rates. Prices are affordable. You can make more money.

7) Bomin Electronics

Rigid, Flexible, or hybrid. Bomin Electronics provides access to all types of PCB circuits. It has been working in the PCB industry since 1994. Over the years, it has developed technically accurate products.

You can expect the following benefits.

- Quality circuits. Don’t underestimate their quality circuits. They have the best quality in the town.

- Excellent shipping services. They ship products to your doorstep. You remain at ease.

8) GOLDENMAX

Golden Max is also famous for its accurate PCB circuits. From essential to advanced materials, it delivers all types of PCB components. Its headquarters is in Shanghai.

Here are some benefits of this supplier.

- Excellent quality. This supplier focuses on quality. You can establish a reliable business with their products.

- Variety of products. All types of PCB circuits are unique.

9) AVARY HOLDING

Avary Holding is no new company that has just started its journey in the PCB industry. Instead, they have 20+ years of experience since their establishment in 1999. From research to designing the circuits, it handles all the manufacturing systems alone.

The benefits of this supplier include:

- Best PCB components. The product is above excellence. You can count on this supplier and grab the best components.

- Largest PCB manufacturer. For four consecutive years, from 2017-2020, it was crowned the most prominent manufacturer.

10) DSBJ

DSBJ is a China PCB supplier from Jiangsu. Established in 1998, it has served its consumers globally. Their focus is to serve consumers with the best quality PCB sourcing opportunities. The essential products are the flexible and rigid PCB circuits.

The benefits include:

- Massive production setup. DSBJ is one of the largest manufacturing companies. The giant plant highlights its reputation.

- Competitive prices. If you are looking for lower prices, look no further than DSBJ. With bulk production, you get lower costs for your business.

11) UETPCB

UETPCB is a professional pcb supplier & pcba manufacturer in Shenzhen. They focus on providing high-quality PCB assembly services

Their service include:

- PCB Prototype & Manufacturing

- Single Sided PCBs

- Double Sided PCBs

- Multilayer PCB

- HDI PCBs

- Flexible PCBs

- Rigid Flex PCBs

- PCB Assembly

FAQs

1) What factors should be considered when selecting components for a PCB?

In electronic component sourcing, you must consider the parts such as resistors, capacitors, or copper. Then, prepare your design and offer it to the supplier. In the manufacturing process, test the product quality instantly.

Also, consider the price to minimize your production costs and increase profits.

2) How do you identify components in PCB?

There are various components of the PCB. You can find out the following parts.

- Batteries

- Capacitors

- Diodes

- Inductors

- LEDs

- Resistor

- Switched

You must have a picky eye and know the shapes and structure of each component to realize it.

3) Do you need certificates to sell PCB components?

Yes. You must disclose your certificates if you sell on Amazon US or Europe. Usually, UL certificates from verified labs are more than sufficient to prove your business worth. Sometimes, you can rely on ISO certificates for your PCB selling process.

4) How do you maximize your profits for PCB component selling?

The primary strategy is to buy at the lower prices and create the margins. Even if the prices are high, you can generate profits by elevating costs. Moreover, selling quality products can make more sales and higher income.

5) Why do I use Chinese manufacturers to source PCB components?

Chinese manufacturers offer a variety of ways to purchase electronic components. These include:

- Lower prices.

- Quality PCB components.

- Large manufacturing plants.

- Easy purchasing process.

- Fast shipping.

Conclusion

In electronic components purchasing, always look for top suppliers. Confirm the deal and hire the PCB experts for inspection. Be sure you are selling the quality.