Your Strategic Partner for

Unlocking China's Sourcing Potential

Net Weight vs Gross Weight vs Tare Weight

This is a complete guide about Net Weight vs. Gross Weight vs. Tare Weight.

In today’s guide, you’ll learn:

International shipping weight

Type of weight

Weight comparison

Package weight

In short: if you want to know more weight against your shipping, you’ll love this new guide.

Chapter 1: The Weight in International Shipping

Overview to Shipping Weight

If you are shipping from China regularly, you are now familiar with the weight terms such as gross weight, net weight, tare weight, and gross vehicle weight. But if you are new to shipping, we will help you understand why they are essential when shipping.

There is a high demand nowadays to keep up with the growth of overseas trade. Buyers who ship from China are from various foreign companies. Cargo vessels are strict with the weight of the containers to ensure safety while sailing.

Importance of Weight

When the containers are loaded in the ship, the dock crews follow a required structure when stacking. The container that weighs a lighter should be placed on top of the heavy container. It is crucial because any error will result in damage or danger.

Weight management when shipping products via sea will reduce the risks of vessel problems. It should not exceed more than its capacity. When the ship is overweight, it can damage the engine that can cause it to sink.

To manage the shipping weight, the three significant weights-Net Weight, Gross Weight, and Tare Weight- are correctly declared and measured. We will explain each one below.

Result of Overloaded Weight

For sure, you know that an overloaded ship can sink. When it sinks, the cargoes worth millions of dollars are lost. But, just as if you are sending packages using express courier services, every package is packed, weighed, and labeled accordingly. It is because the plane should not carry beyond its capacity.

You can look at this quick video (2:05) and see what an overloaded ship looks like. In the same way, when the loaders do not arrange the containers appropriately, they can collapse. It happened in the port of Hongkong. Click on the photo to watch.

Chapter 2: 3 Types of Weight

This chapter will explain in detail what gross weight means, net weight, and tare weight meaning is. Then, to understand it well, we will show some examples and explain its computed formula.

Net Weight

To put it simply, the net weight is the product’s or good’s weight. Net weight means, no packaging included or not placed in a container.

It also refers to the total number of stock or goods on the vessel, excluding the weight of the container, packaging, or other cargo protection equipment, like shelves or pallets, that are there to keep the goods safe.

So when you are declaring this weight, net weight means, just the product alone and no box or packaging. So, for example, when your product is a Bluetooth speaker, you don’t indicate the weight, including the safe packaging and box- only the speaker.

Among shipping terms, the net weight definition is the most common. Here’s an easy formula to remember for net weight:

Net weight= Number of products X Weight of the product

For example: If you are ordering 20000 pcs of a Bluetooth speaker that weighs 150grams, the net weight meaning, just the product total weight, is computed as 20000 x 150grams= 3,033,952 grams, and when converted in Kilograms, it will be 3033.952 kilograms.

The net weight definition and the formula are easy to remember. And the supplier always gives the product net weight meaning no box or packaging is included.

Gross Weight

Now let’s talk about gross weight. If the net weight is just the product’s weight, gross weight is the weight that includes the packaging, shelf, and container weight. Gross weight meaning includes the palette where it will be stored and the container where the pallet will be placed.

The total weight of the items or goods, including all packaging but excluding the tare weight of the transport unit, is referred to as the gross weight. Gross weight meaning does not include the weight of the transport unit before they load the cargo.|

There is also a formula to get the gross weight. If we go back to our previous example of Bluetooth speakers, we will get the gross weight by using this formula:

Gross Weight= Product Net weight + Packaging Weight + Product Shelf Weight + Container Weight

Now let’s apply it to our example. To compute the total gross weight, here’s what it should look like:

Product Net weight – 3034kilos (rounded off 3033.952 kilos)

Packaging Weight – 1000 kilos

Product Shelf Weight – 800 kilos

Container Weight– 2000 kilos

Gross weight meaning the total of all the numbers above, would be = 6339 kilos.

After the gross weight definition, we will discuss tare weight.

Tare Weight

Now let’s go to the next weight= the tare weight. Tare weight means, the officially recognized weight of an empty automobile, vehicle, or container. Once it is removed from the gross weight, it is the net weight of cargo or shipment, from which fees can be determined.

When it comes to logistics, the entire weight of the tractor and trailer while the vehicle is empty, that is, when there is no product in the trailer, is known as the tare weight. Unladen weight is another name for tare weight meaning, “unloaded cargo” weight.

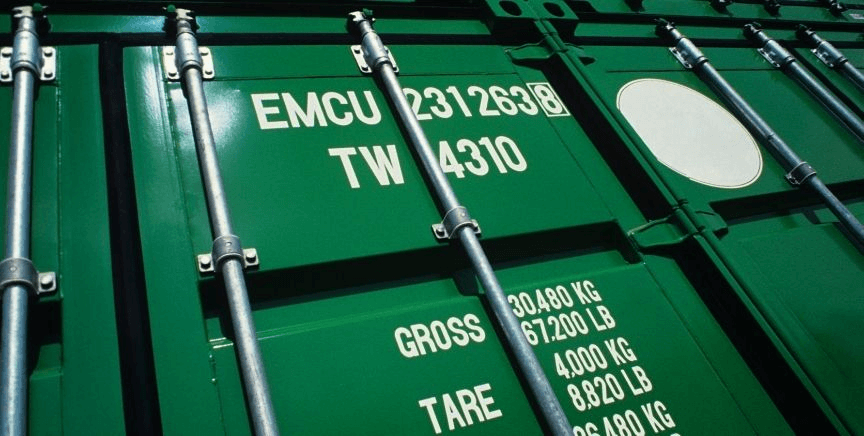

You would notice that the tare weight is printed on intermodal containers to help you figure out the gross weight when you’re loading up your equipment.

Thus, the gross weight and tare weight of the container is essential to ensure the shipment is legal on roads and bridges. The total weight of a truckload or intermodal freight is necessary and how the weight is spread out on the tractor and trailer.

So in our sample above, the tare weight is the container weight which is 2000 kilos. The tare weight meaning is quick to remember. Again, the tare weight of the container is the weight when the vehicle is unloaded.

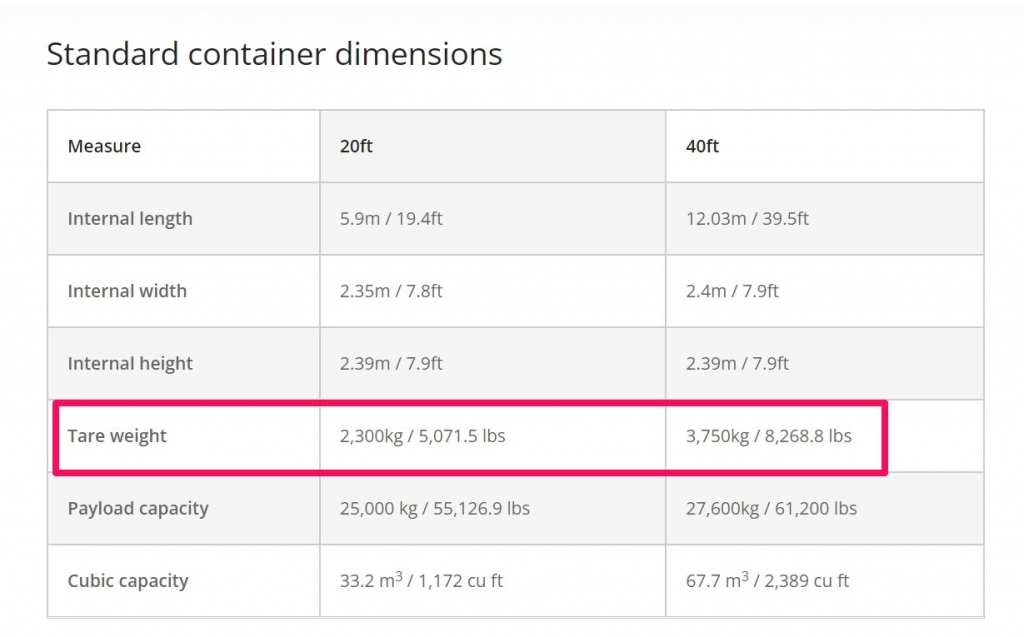

A standard weight of a tared container for international shipping is 1800 kilograms. It is heavy, right? Because a regular trailer tare weight is only 330kgs. But for containers, for example, a Cosco container tare weight for a 40ft steel container is 3,700kg.

For a 20 ft container, tare weight can be up to 2500 kilograms. The tare weight of the containers varies from their size. Here’s a sample dimension and tare weight from a container supplier:

Credits to: Container Xchange

There are other container shipping services available aside from the example above.

You can use this link if you need a CMA CGM container tare weight finder. For Maersk tare weight, they also have a lineup for different kinds of cargo. OOCL container tare weight has its own specifications too. Same as for MSC container tare weight.

So the tare weight, net weight, and gross weight are three requirements when shipping, so you should be knowledgeable about it.

Chapter 3: International Shipping Terms for Weight

Now that you’ve learned the net weight and gross weight and tare weight meaning, here’s a simple glossary of some weight terms in shipping. If you are confused about some terms like the gross trailer weight, total gross weight, or gross trailer mass, the following details will help explain.

Is the gross vehicle weight meaning different from gross combination weight? Let us tackle some of these vehicles and container weight terms below. The first one in our list is the verified gross mass meaning.

Verified Gross Mass

The Verified Gross Mass meaning, also known as the VGM, is the total weight of all cargo, including packing and dunnage, plus the container’s tare weight. The verified gross mass (VGM) can be determined in two ways: by weighing the packed container or by computation.

Unless the shipper notifies the ship’s crew and port officials that the container’s Verified Gross Mass has been given to them, it can’t be loaded on the ship.

Incorrect weight declarations have resulted in several accidents in the past. They pose a threat to the safe carriage of containers at sea and to those who work aboard ships. They must follow the stated guideline.

The shipper is responsible for the verified gross mass meaning, and they should provide the information in advance. Otherwise, it can cause a delay in the vessel’s scheduled trip. It can result in money loss for the shipper and carrier.

Submitting the verified gross mass meaning, individually weighing all cargo items and contents of the container. It includes the weight of the packing material, pallets, or dunnage and adding their weights to the container’s tare weight.

Now that we have defined the verified gross mass meaning, the next one to understand is the gross vehicle mass.

Gross Vehicle Mass

The Gross Vehicle Mass (GVM) of a vehicle is the total weight that it can apply to the ground at one time (also referred to as the GVW Gross Vehicle Weight).

The Gross Vehicle Mass contains the weight of the following:

- The cab chassis (tare weight)

- Body

- Weight of equipment.

- Accessories

- Fuel

- The driver

- Weight of passengers

- The weight of cargo

The weight of a trailer is not part of the gross vehicle weight unless a portion of the trailer weight is placed onto the truck (for example, weight on the towing attachment). While traveling on the road, the Gross Vehicle Mass is the maximum loaded weight that a sturdy vehicle can carry.

In summary, the Gross Vehicle Mass refers to the vehicle’s maximum weight and the load it can carry, as determined by the vehicle’s manufacturer. Commercial vehicles are medium and large goods vehicles with a gross vehicle mass of 3500kg or over.

Gross Vehicle Weight

The Gross Vehicle Weight means the sum of the vehicle’s weight when it is empty and the max payload weight that the vehicle can transport.

It is the maximum cargo weight that a container can hold, excluding its tare weight. Containers are equipped with CSC plates, which display the payload that the container is permitted to transport.

When considering the truck’s weight, chassis, and container, the maximum gross vehicle weight definition in most regions cannot exceed 80,000 lbs. (36,287kg), which is the fundamental legal limit for US highway transport.

Although some states allow for more considerable weight limitations, the cargo weight must be confined to the above maximums. If the weight is not uniformly distributed throughout the container, the container may be liable to an axle weight violation.

The vehicle’s overall weight, including its cargo, is referred to as the gross vehicle weight or GVW. The difference between the vehicle’s empty weight and its gross vehicle weight (GVW) is not statistically significant in cars and small light trucks (around 1,000 to 1,500 lbs.)

The payload capacity refers to the total amount of cargo weight that you may safely transport in addition to the empty weight of the vehicle. The gross vehicle weight trailer is the sum of the payload and the trailer’s weight.

Payload capacity share for the heaviest trucks and tractor-trailers is 200 percent, which means they can transport twice as much as their empty weight when loaded to their maximum capacity.

Medium-sized vehicles or truck gross weight classes 3-6 have payload capacity shares ranging from 50 percent to 100 percent of the total capacity.

Gross Trailer Weight

The gross trailer weight includes the weight of the trailer itself and everything loaded into it. The gross trailer weight includes all cargo, passengers, equipment, liquids, and everything there is.

You must know the GVWR or GTWR not to exceed the maximum allowable weight when fully loaded. It is known as the Gross Vehicle Trailer Weight Rating. It refers to the gross vehicle weight meaning, the maximum amount of weight the vehicle can carry.

Gross Combination Weight

Gross Combination Weight is the maximum loaded weight of a truck or tractor plus the trailer or semitrailer designed for the truck tractor. The manufacturer provides it.

Without the manufacturer-specified number, GCW is calculated by adding the power unit’s gross vehicle weight (GVW) to the whole weight of the towing unit, including any load.

Gross Combination Mass

It is the maximum loaded weight of the towing vehicle, along with any trailers, that can be hauled while traveling down the road.

At any time, Gross Combination Mass is the maximum combined weight of the vehicle, trailer, and any cargo that the vehicle and trailer haul.

Chapter 4: Weight Comparisons

After knowing some of the basic shipping weight terms like gross weight meaning, net weight meaning, you are now familiar with the net weight and gross weight difference. We will find out about net weight gross weight or trailer tare weight like a Cosco container tare weight.

1. Net Weight vs Gross Weight vs Tare Weight

Net weight is the weight of the good or product alone without any packaging material. The gross weight is the sum of net weight and tares weight. At the same time, tare weight is the container’s weight when empty.

The net weight and gross weight matter when shipping. To put in a summary, here’s a simple formula for gross and net weight:

Gross weight = Net weight + Tare weight

Net weight = Gross weight – Tare weight

The tare weight and net weight gross weight of your shipment are necessary information to be accurate when shipping. The net weight and gross weight applies to the product you want to ship into the container.

2. Payload vs Tare weight

The payload, also known as net weight, is the maximum weight that a container may hold in terms of cargo or contents. The maximum payload of a container should not be exceeded.

The Tare Weight (also known as unladen weight) is the empty container’s overall weight. By deducting the weight of the internal items from the container’s gross weight, the weight of the internal products can be calculated.

3. KERB weight vs. Tare weight

The weight of a vehicle with a full tank of gas but no extras is known as kerb mass. It is the vehicle weight without passengers or baggage but includes all of the components required for proper vehicle operation, such as water, gas, and other standard equipment.

The weight of a vehicle fresh off the assembly line with only 10 liters of fuel is known as the tare mass. The tare weight is the vehicle weight before any further accessories are installed but before any cargo is loaded.

4. Dunnage vs Bracing

When goods are loaded, transported, and unloaded, dunnage is used to keep them from getting broken or scratched. Whether the items are sent by rail, road, or sea, keeps them from moving.

Dunnage also protects goods and packaging from getting contaminated or getting wet most of the time. Dunnage helps improve customer relationships and makes it easier to load fragile goods by protecting them from damage.

Many types of dunnage, like dunnage bags, can be reused and recycled, which makes them both sustainable and environmentally friendly. This is called “dunnage,” and it helps to stabilize a cargo load, keep things in place, absorb vibration, and fill in any gaps in shipping containers and vehicles.

On the other hand, bracing means keeping the load from moving up and down. When there isn’t enough bracing, a load can jump over the blocks that hold it down. And if the braces don’t have proper blocking, they won’t stay in place.

When shipping goods in a sea container, more durable goods don’t always need to be in full crates. Instead, they can be blocked and braced in the sea container itself.

There is less wood used when blocks and braces are used instead of a full crate. This means that the cost and weight of the box will be less. It also makes the object safer. It’s important to block and brace the cargo so that it doesn’t move along its long axis.

Bracing a cargo is a way to make sure that cargo doesn’t get damaged while it’s being moved. When loading goods to a container, they are very likely to move around in their container if it does not max out the inside width and length space of the shipping container.

Chapter 5: The charge weight for different delivery (freight charging unit)

Express

When shipping your items via Express like FedEx, your freight is calculated based on its classification. The different factors for determining the cost are:

1. Item you ship

2. Dimension and weight

3. Item’s value

4. Loading requirement and other safety precautions

5. How it fits inside the trailer with other packages

You pay the gross weight when shipping by calculating the density. The density is the length, width, and height. The easiest way is to use their classification tool for an easy estimate.

If you are shipping bulk goods like printed materials, automotive parts, furniture, apparel, or appliances- it will be classified to determine the fee. The higher the classification, the more expensive is the shipping cost.

Another factor is the type of packaging you will need for your freight, whether it is a board or box, plastic boxes, wood pallets, or steel boxes. The shipping amount varies based on item classification.

Depending on your preferred courier, they also offer flat-rate freight. For example, the FedEx Freight box allows you to send packages under 1200 lbs. That means you can send different items inside the box for just a flat rate as long as it does not exceed 1200 lbs. gross weight.

Air

When it comes to air freight shipping, weight and volume are key factors. Air carriers will charge by either volumetric weight (also known as dimensional weight) or actual weight, depending on which is more expensive.

If the volumetric weight of a product is more than the actual weight of the product, the volumetric weight is the chargeable weight. Air cargo prices now range from $4.00 to $8.00 per kilogram.

Not all shipping companies have the same rate. However, they have a freight calculator from their website that you can use to get an estimate. They can also quote you based on your requirement. You pay for the gross weight.

Aside from the weight fee, the following are also charged:

- Surcharges for fuel

- Surcharges for security

- Handling fees at container freight stations and terminals

- Transfers from the airport

- Brokerage services for customs

- Delivery and pick-up

- Insurance for cargo

- Charges for extra packaging

Sea

For the sea freight, the gross weight is measured for the chargeable weight. Airfreight becomes unaffordable for shipments weighing greater than 500 kg.

The cost of ocean freight is roughly $2-$4 per kilogram, and a shipment from China to the United States will take 30-40 days or more.

Aside from gross weight, some additional charges will incur for the following:

- Surcharges for customs security

- Station for Container Freight (these are the consolidation charges, and apply for LCL only)

- Charges for terminal handling (charges by the port authority)

- Brokerage services for customs

- Delivery and pick-up

- Insurance

- Charges for extras (fuel surcharges, handling hazardous materials, storage, packaging)

- Charges for routing

The charges are not fixed as it will depend on the company where you will get the ocean freight service. They can make a quote for you based on your package or shipment details.

Chapter 6: Tips on Package Weight

The shipper’s main concern is the cost and charges of the cargo and its safety, of course. Before we even think about the net gross weight, gross tare net, and other weight terms, we think about how the packages can arrive in their best condition.

So here are some tips that can help reduce the package weight when shipping out.

Reduce shipment weight

One way to cut down on shipping fees is to make your packages lighter, so they don’t cost as much to send. Most of the time, your product has a fixed weight. There are ways to change the packaging to make your shipment lighter and save you money on shipping costs.

Many products are packaged and then put into another box to be shipped. If you can get rid of the inner packaging and just ship the product in one box, you’ll be able to lower the weight and the size of the package.

Use lightweight boxes

Boxes come in different thicknesses and grades. It gives you an overview of how much weight each box can hold. You might be able to use a lightbox for your products that don’t need a lot of protection.

When you package something, use lightweight materials like bubble wrap, crinkle paper, or filler paper. To cut down on the weight of your package, use a lighter package like a polybag or padded envelope. This could also qualify you for a cheaper mail class.

There are also different types of boxes, like mailer-style boxes, which are more durable but have more cardboard and weigh a little more. You can cut the weight of your shipments by choosing the right box or package for your goods.

Reduce unnecessary packaging

This tip is applicable for those who have online shops or Amazon stores that ship out to their customers.

When you choose the right size box or packaging for your products, this will cut down on the weight that comes from extra packaging and box material. If you sell a lot of different things or your customers usually buy more than one thing, this can be a bit of a challenge. You need to switch to a practical way.

Anything you can do to lower the weight and packaging should save you money when you ship out. Make sure you look at your product to see how different or additional packaging can affect shipping costs before you make changes to your packaging.

Chapter 7: FAQs

As we almost approach the end of this article, remember that weight terms are important when shipping products.

Though terms like container gross weight, combined gross vehicle weight, or empty weight of the trailer as well as vehicle tare weight and truck tare weight may be complicated, they are all part of the process to ensure safety in shipping and delivering goods around the world.

Here are some of the FAQS you need to know now:

What happens if the container is overweight?

Containers that are too heavy are a critical concern of a ship. When the container vessel is overweight, it results in improper loading or stowing. It will affect the ship’s strength. Sometimes, containers get lost due to overflow.

When the container ships are massive, and containers are stacked higher, it causes damage to the terminal and the port equipment. It can also cause injuries to the workers when they load or unload shipments in the container yards.

What is the maximum weight allowed in a 40ft container?

The empty weight of a 40-foot container is 3,750kg. It can be filled to a maximum weight of 29 tons (26,300kg). It would also depend on the shipping line, the nature of the cargo, and the specific details of the shipment to figure out how much cargo you could fit on your truck or ship.

With the SOLAS Convention in place, the rules for preventing containers from being too big to have become stricter. SOLAS changes say that the shipper has to make sure that the weight of the container is correct before it can be loaded on a ship.

The maximum weight of a container varies depending on the manufacturer and the material it is made of. Doors and the CSC plate show the container’s capacity and dimensions.

Does gross weight include tare weight?

No. It is vital to note that the gross weight is the total weight of the products transported, including all packing materials, but does not include the tare weight of the transport unit. The tare weight of a transport unit is the weight of the unit before any cargo is loaded.

You can see the tare weight of a container on the container. It goes along with the other important information about the container, like how big it is.

For most shippers, when they get the gross and net weight, they add the product’s weight, both the tare weight and the weight of their cargo. It is how they estimate their fees. The gross weight definition or formula is :

Gross Weight= Product Net weight + Packaging Weight + Product Shelf Weight + Tare Weight

What is the result when the weight of the cargo container is incorrectly declared?

An incorrectly declared weight of the cargo can cause damages, injuries, and money loss. It results from collapsing of containers or a sinking ship. Containers that have been declared as heavy by their shipper and used for stow planning and on-board stability can have very different weights than they actually are if the shipper is wrong.

In addition, if the weight of a container is wrong, it can cause a stack to be overloaded, which can put too much pressure and force on the containers and their lashings.

Some of the unfortunate scenarios of overweight containers due to misdeclaration put the terminal, the ship, the dockers, and more to losses and life-threatening risks.