Your Strategic Partner for

Unlocking China's Sourcing Potential

Purchase skills | How to make a purchasing plan to avoid out of stock?

Let’s talk about the production cycle first

The production cycle here is defined as the time period from the beginning of pre-production samples to CRD (Cargo Ready Date) after the order is placed.

According to the different nature of the order, it is divided into:

- First Time Buy or Replenished.

- Supplier Export Order (Direct Import) or Supplier Domestic Order (Domestic)

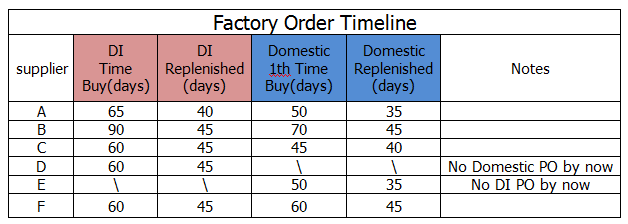

Different suppliers have different capacities, so if you don’t do data processing, it will be very messy. For example, after our simple table statistics, the production cycle of several suppliers is rough as follows:

Note: Supplier’s export orders generally involve third-party testing and inspection, while domestic order requirements are relatively simplified. Therefore, the production cycle of DI orders will be longer than that of domestic orders. The above is a simple graphical table of the production cycle of each supplier.

Let’s look at the order rules

Before we talk about the rules of ordering, for the convenience of understanding, we divide the order items into two types:

- Promotion Order (one-time order)

- Inline Order (long-term order items with return orders)

The promotion order is obviously over after the first time buy (1st Time Buy) process. In addition to the first time buy, Inline Order will also include replenishment orders.

Then take the 2021 spring project as an example.

Generally, purchasers should place all orders for 2021 spring projects to suppliers before the end of September 2020. Why? This comes back to the first point, the factory’s production cycle and relatively fixed shipping schedule.

If an order is placed on September 20, according to demostic’s 1st Time Buy production timeline, (order date + production cycle) the fastest shipping time is November 5, and the latest shipping time is November 29. It seems to be early, more than a month before 2021, but it is not.

After the goods are dispatched, we also need to calculate the time for the goods to be transported by sea. Excluding some countries of Southeast Asia and the western United States where the transport time is shorter (about 20 days), the shipping time for the goods to other countries and regions is about 40 days. Including the customs clearance time, the entire shipping time is around 55 days.

In this way, the time for the goods to arrive at the buyer’s warehouse has reached January 24, 2021. The buyer also needs to send the goods to different selling points from his warehouse according to the retailer’s order, and it will take some time on the road. The spring products will start to sell on February 5th.

By analogy, 1st Time Buy’s order placement time can be traced according to the project (Spring 2021, Christmas Promotion, etc.). Christmas sales promotion items will be placed no later than the end of May.

It is not difficult for us to find out. Suppliers usually start recommending Christmas promotional items before April, and buyers will receive a lot of development letters from suppliers in March and April. At this stage, Buyer and Sales began to prepare and confirm the promotion goods, it was the best time to start preparing this year’s Christmas promotional projects. Only by preparing in advance can buyers be able to grasp the peak sales season and avoid risks.

Finally, the order rule of returning orders.

The order rule of the Replenished Order mainly affects the supplier’s material preparation and scheduling. Customers should make plans and arrange orders according to the supplier’s replenishment production cycle, their own warehouse inventory and sales expectations.

For familiar suppliers, buyers can inform quarterly or annual Order Forecast to facilitate suppliers to order materials and arrange production based on this. Centralized procurement of materials can reduce the cost of materials purchased by suppliers, and the prices that suppliers give you will also be more favorable.

This shows that precise expectations and plans are very useful. However, buyers must be reasonable for Order Forecast, otherwise it will cause excess inventory or insufficient inventory to affect sales.

As buyers, we should have good insight and prepare for the peak sales season in advance. Monitor your product inventory at any time and make a corresponding stocking plan. Friendly cooperation with suppliers to reduce procurement costs to achieve a win-win situation.