Your Strategic Partner for

Unlocking China's Sourcing Potential

Purchasing Skills | What is pad printing and how long does it take to print a logo?

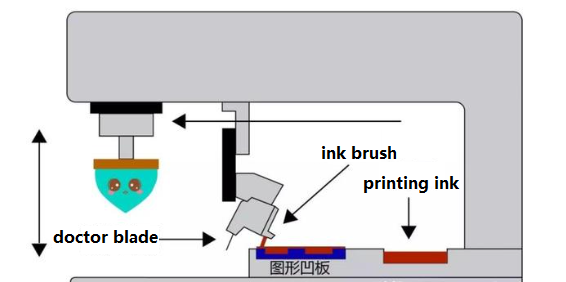

The principle of pad printing

The pattern to be printed is first made into a steel plate (or copper, thermoplastic) intaglio by film etching, and then a curved pad printing transfer head made of silicone rubber material is used to dip the ink on the intaglio plate onto the transfer head. And then press on the surface of the object to print text, patterns, etc.

Pad Printing process is somewhat similar to the principle of the seal stamping.

Pad Printing is suitable for the printing of concave and convex surface.

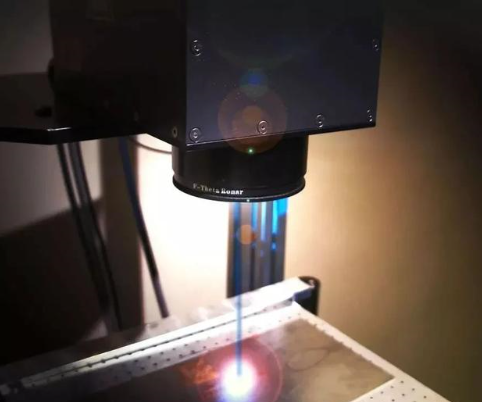

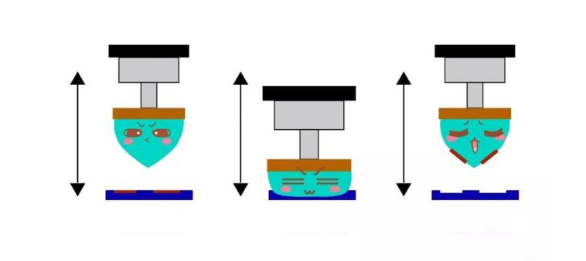

Working gif of the pad printing

Due to pad printing can be used for small area, irregular concave-convex products , has a great advantage. About 50% of electronics, toys, plastics and other products use pad printing technology for pattern printing.

The process of pad printing:

Making the text, patterns, etc-make the film — drying steel plate-printing ink selection/printing ink adjustment-machine adjustment-drying-printing

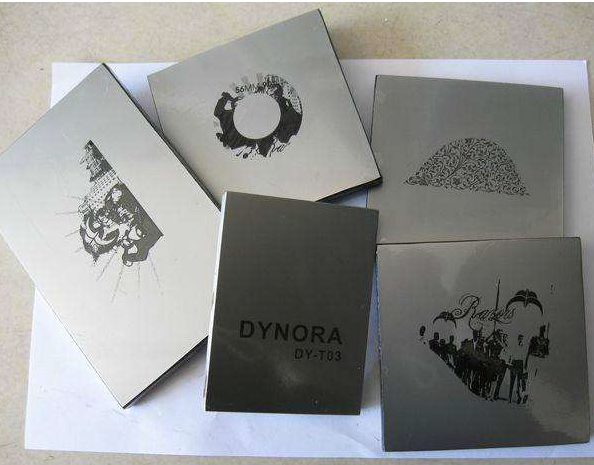

The graphic content of pad printing needs to be etched on the steel plate first, After the steel plate is cleaned, the photosensitive glue is evenly coated on its surface, and then a printed film with graphic and text is attached. Exposure to ultraviolet light will harden the area without graphics. Rinse with developing water to make the pictures and texts on the film appear on the steel plate, and pour the corrosive solution to make the pictures and texts corrode on the steel plate not more than 0.5 mm deep. You can also directly u

se laser to corrode graphics and text on the steel plate.

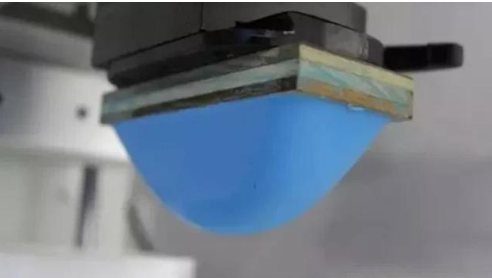

Finished Steel Plate

The transfer head is made of elastic silicone, and the shapes are round, rectangular and square. This kind of shape can better contact the etching plate and the printed product. Transfer the graphics to different shapes on the flat steel plate, in this process, due to the pressure of the transfer head and the different working surface, the transfer head will be deformed. In order to make the transferred graphics not deformed, it is necessary to choose different soft, hard, and large transfer heads according to the product shape to adapt to the deformation of the transfer head to achieve the ideal printing effect.

Apply the ink to the etching plate, a doctor blade will scrape off the excess ink, the remaining ink will remain in the etching pit.

A transfer head made of silicone sticks the ink in the concave to the surface of the head.

Characteristics of pad printing:

1. Wide Range of application: Pad printing is generally applied to workpieces that cannot be processed by silk screen printing such as grooves and the back of the workpiece. Since the pad printer is an automatic device with high precision, it can be used for polychrome printing. The number of colors can be unlimited in theory, but in actual operation it will not exceed 7 colors.

2. Easy to operate: The device is fully automatic

3. Low cost: In addition to equipment than silk screen printing machine much more expensive, other cost factors and silk screen printing the same

The cost of pad printing a logo is the same as the cost of silk-screen printing a logo, 0.2CNY per color

The steel plate cost 80-100CNY.

The time required for pad printing is 1-2 days.